The water fill is located on the starboard gunwale, just forward of mid ship. To check water level, open the floor hatch in front of the console’s forward seat. If you look into that hatch going back towards the aft, the holding tank (approximately 13 gallons) will be visible as well as the water level in the tank.

Author: admin

Where can I add a transducer on my stepped-hull boat?

When installing a transducer on a stepped-hull boat, proper placement is critical for accurate sonar performance. The ideal location is typically just forward of the first step and slightly off center, on the starboard side of the keel. This positioning helps ensure the transducer remains in clean, undisturbed water flow, which is essential for reliable readings at speed.

Key Guidelines:

-

Avoid stepped surfaces: Mounting on or near a step can disrupt water flow and cause turbulence.

-

Stay below the waterline: Ensure the transducer is fully submerged at all times.

-

Avoid trailer bunks or strakes: Be sure the transducer is not placed where it could be damaged during loading or unloading from a trailer.

-

Consult the hull manufacturer if unsure: Every hull design is different, and it’s best to verify recommended mounting areas with your boat’s manufacturer or a certified installer.

Proper installation enhances sonar clarity and reduces signal loss or erratic depth readings. When in doubt, professional installation is recommended.

I have more water than usual coming from my Spyder’s drain plug. What should I do?

Your vessel is equipped with an automatic bilge pump which ejects water out of the aft starboard. With that, should the bilge be inoperable or have an issue, it’s possible to see more water than usual. Your vessel also has scupper plugs throughout which all drain into the bilge. Over time, these plugs may become brittle and thereby no longer channel water efficiently. In either case, we recommend you take your vessel to the nearest Spyder dealer or marine service center for service.

As a reminder, your first point of contact for all issues or parts requests should always be your local CRI dealer. As an OEM, we do not provide direct-to-owner support as this interferes with the vital role our dealers serve. Should your local CRI dealer at anytime have an issue which they can not resolve, that issue can be escalated to us on your behalf.

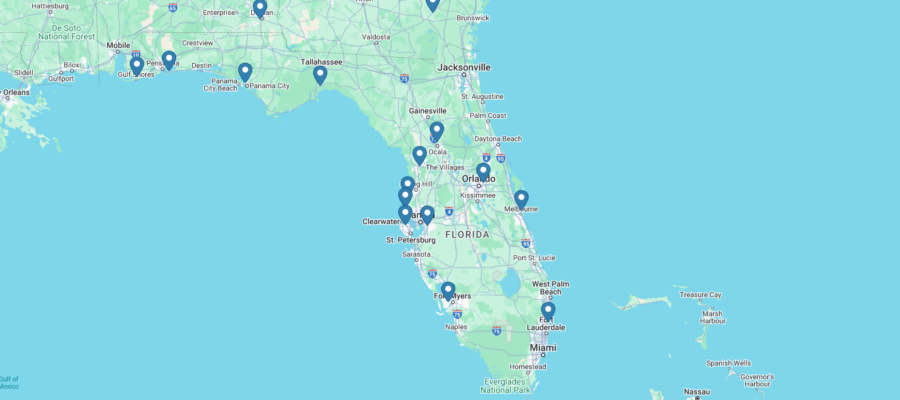

CRI Welcomes New Florida Territory Manager – Sean Hickey

CRI Dealers – We’re excited to announce that Sean Hickey is joining the CRI team as our newest member, overseeing the Florida territory. With over 35 years of boating and leadership experience, Sean brings a wealth of knowledge that will undoubtedly elevate our operations and strengthen our relationships with dealers across the region.

CRI Dealers – We’re excited to announce that Sean Hickey is joining the CRI team as our newest member, overseeing the Florida territory. With over 35 years of boating and leadership experience, Sean brings a wealth of knowledge that will undoubtedly elevate our operations and strengthen our relationships with dealers across the region.

Can you tell me how the battery switches work within my boat?

- Charging System: Both the house and engine batteries are charged by the engine. In boats with mechanical engines, a transfer switch is used. This switch monitors the voltage of both batteries and directs the charge to the one with lower voltage. For Suzuki and Yamaha Digital engines, a dual output alternator is used instead. This alternator can charge both the engine and house batteries separately, eliminating the need for a transfer switch.

- Battery Usage: The house battery powers most of the boat’s functions such as bilge and fish box pumps, electronics, and lights. Meanwhile, the engine battery is responsible for starting the engine and powering the power assist steering.

- Crossover and Safety: A crossover switch is available for emergency situations. If either the engine or house battery runs low, this switch acts like a set of jumper cables, allowing one battery to assist the other. However, it’s important to return this switch to the off position after use to avoid draining both batteries.

- Factory-Installed Battery Charger: Typically, the factory-installed battery charger is set up to charge only the trolling batteries. If a boat doesn’t have trolling batteries, or if an additional charger is added, the setup can be reconfigured to also charge the house and engine batteries. This is particularly useful when the boat is docked in water for extended periods, ensuring that essential functions like the bilge pump remain operational without draining the batteries.

Where can I find a trailer guide for the Sea Born SX281 offshore?

The following attachment is a trailer guide for the Sea Born SX281 offshore.

Where can I find a trailer guide for the Sea Born SX281 offshore?

The attached file is a trailer guide for the Sea Born SX281 offshore.

What size hydraulic hose is installed on Sea Born FX22?

In almost every case, the Sea Born FX22 will utilize a 16′ hydraulic steering hose.

What is the steering cable length used on a Sundance B20 and B22 skiff?

The steering cable length for the Sundance B20 and B22 models is 16 feet. Please ensure that this measurement is correct before proceeding with any repairs or maintenance on the steering system.

What size trim tabs are recommended for a Sundance B20 or DX20?

When adding trim tabs to your vessel in the aftermarket, we recommend 6×9 trim tabs for the B20 and DX20.