In many of CRI’s skiff models, there are channels that run along the hull or the deck. Those channels are built into the boat to be used for running rigging (IE. Wires) along the vessel.

Author: admin

What is the length from the waterline to the top of the bow on an LX24?

The top of the bow to waterline measures approximately 32″.

This question is typically linked to the desire to install an aftermarket trolling motor. In most cases, a 72″ should be fine as it is of the more commonly used length. However, for owners who plan offshore runs and to use their trolling motor as an active anchor, you may want a longer shaft.

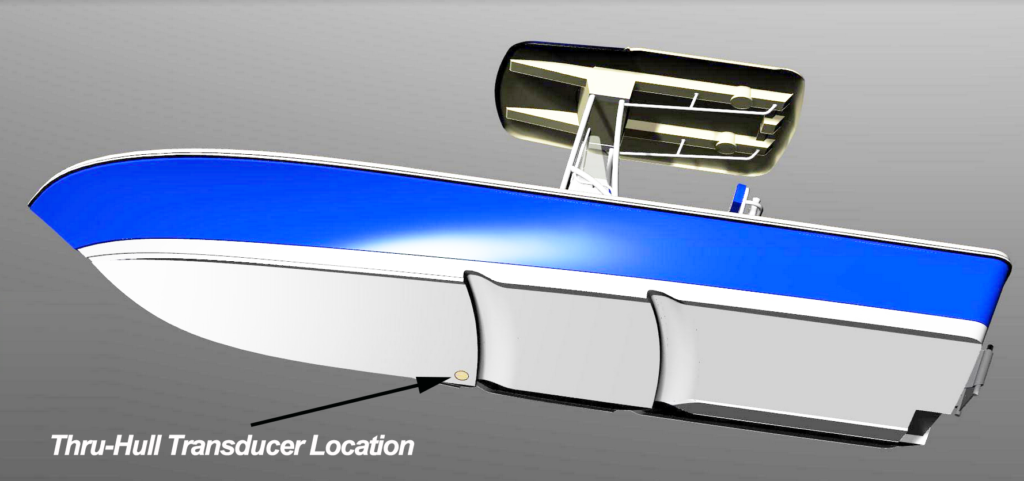

Where is the transducer located on my stepped hull boat?

In most cases, the through-hull transducer for boats manufactured in the FX, LX, & SX class will be located forward of the steps. The purpose of this location is to ensure that the transducer gets a clear reading.

Should the need arise to service the transducer, most models have access hatches on, around, or underneath the console-front well. Prior to attempting to self-service and potentially voiding your hull warranty we STRONGLY recommend contacting a local CRI dealer for assistance.

Where can I purchase replacement parts for my boat?

As we do not sell replacement parts directly to the public we recommend you contact your local CRI dealer for assistance. To help your dealer to locate the parts you need, be sure to provide your vessel’s hull identification number.

Should you need assistance locating a dealer, please visit https://www.criboats.com/mydealer/

Tip:

Failing to provide your boat’s serial number (or other requested information) with your parts request will greatly delay your dealer’s ability to provide you with timely service.

What size trolling motor should I use on my FX Bay boat?

In most cases, we recommend a 12v trolling motor with a minimum of 45 lbs pounds of thrust. As for the length, most owners use the 54″ shaft though this will vary greatly depending on use and conditions.

Where can I find a prop chart for a Sundance or Sea Born SV boat?

The following document contains prop chart for many SV models including the SV171, SV186, SV205, and SV23.

Version 1.7 dated July 1, 2010

What size trolling motor do I need for my Sundance B20, DX20 skiff?

In most cases, we recommend a 12v 45 lbs trolling motor. As for the length, most owners opt for the 42″ length variant.

Can I take my boat to any CRI dealer for service and support?

Yes! Understanding that you and your boat may relocate during the course of your ownership, we invite you to take your boat to any of our dealers for service and support. To find a dealer, simply use our online locator, and reach out the desired dealer to schedule service.

On the topic of awesome service and support, we always welcome your thoughts and ask that you share your opinion by completing our dealer feedback and review form found below.

How do I operate my aerated bait well?

This article is intended to provide general operational instruction for aerated bait wells found on Sea Born, Sundance, and Spyder boats.

Operation

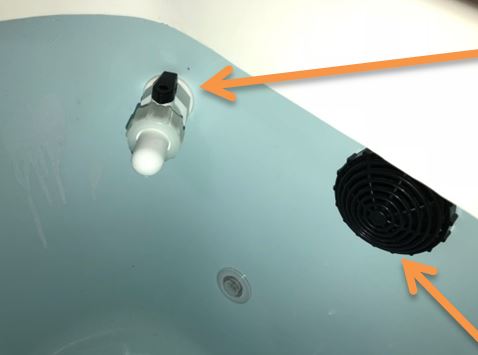

Locate the rubber drain stopper(s) found inside the blue accessories pouch. See Figure 1

Next, open the desired bait well(s) and locate the drain opening at the bottom. Prior to starting the flow of water, firmly place the stopper in the bottom of the well. Next, locate the aerator spray head found near the top of the well. See Figure 2

Notice the spray head has a small black lever on top which may be turned 90° to the left which is the off position. To open the valve to the “on” position and allow the flow of water, turn the spray head to the center or inline with the spray head body. See Figure 3

To start the flow of water, from the console instrument panel, turn the Bait Well into the on position. Immediately, water should begin to fill the well chamber. Once water reaches the level of the overflow screen, located beside the spray head, water will begin draining overboard through the thru-hull drains located on the transom. See Figure 4

Regarding baits, most need less water changes per hour than the pump will supply. For example, shrimp and crustaceans need approximately 5 changes whereas fin baits need 7 to 10. Unless the operator has reduced the fill rate, the pump head will supply about double the needed amount. Given this, typical use in most cases would position the fill lever at a 45 degree angle.

Regarding Dry Storage

If the lever is in the open position and the pump is turned off, water from the high speed pick-ups will flow into the well when the boat is running. If you intend to use the well for dry storage or as a drink cooler remember to close the lever to the 90 degree off position.

How to clean the caulk in my boat’s seams?

The “caulk” used in your CRI boat is a UV resistant, polymer sealant made specifically for permanent elastic seals. Occasionally you may notice what appears to be mildew forming on the surface. This is actually hydrocarbons primarily from air pollution (typically auto exhaust) that forms a film on the surface of the sealant.

To clean, use mineral spirits and a soft cotton rag to scrub the sealant surface. Several applications may be required. Once clean, wash the area with a large amount of a degreasing liquid detergent (i.e. ”Dawn”) and plenty of fresh water.

Remember to use personal protective equipment such as solvent resistant gloves and protective eyewear.

Product Information

Sikaflex®-521 UV

Sikaflex®-521 UV is a multi-purpose, UV resistant, non-sag, elastic, one-part silane-terminated polymer sealant, which cures on exposure to atmospheric moisture to form a durable elastomer. Sikaflex-521 UV is solvent and isocyanate free.

Use

Sikaflex®-521 UV bonds well to a wide variety of substrates without the need for special pre-treatment and is suitable for making permanent, high strength elastic seals. Compatible substrate materials include wood, metals, (particularly aluminum including anodized components), sheet steels (including phosphated, chromated and zinc-plated components), metal primers and paint coatings (two-part systems), ceramic materials, fiberglass, plastics and glass.

Characteristics and Advantages

- Very low VOC/solvent free

- Silicone and PVC-free

- Isocyanate-free

- High electrical resistance

- Resistant to aging and weathering