FX19 Vapor

FX17 Flicker

Transom mount transducers—while they are the easiest to install, can be the hardest to get working properly at speed. Fine

adjustments are needed for good high speed performance.

Please check the following for troubleshooting your transom mount transducer:

The picture below illustrates lowering and angling your transom mount.

One thing every all of us boaters comes to understand, we’re at the mercy of the weather and checking out the forecast is just part of the deal. To help you get a quick read on the forecast, we’ve worked up this quick list of useful weather apps for your tablet and smart phone.

We recommend using 3M 5200 marine sealant.

The approximate dry weight of the 2005 SV17 is 1,430.

In 2005 all models used 3M 5200 marine sealant.

The best location for jack stands would be both sides of the transom and one under the keel.

This knowledge base entry is meant to serve as basic information for the installation of a third-party, aftermarket top. Before attempting any such an install, we strongly recommend you seek professional assistance.

When installing a top on the FX21 Bay, please note that the Front legs of the top need to go into the small notches which intersect the front console’s face and console-front seat. In the rear, the back legs need to go inline with the back face. Below the floor, there are aluminum plates for the legs of your top. Additionally, the floor is cored with 3/4″ structural foam with glass on both sides and then the 1/4″ aluminum plate.

Please Note: Located at the center of the cockpit under the floor board is the fuel tank, when adding your top be aware of this location and avoid drilling in this area. Also be aware that the fuel fill hose is on the port side about 10″ forward of the back face of console. From the inspection hatch, you’d be unable to determine the fuel line’s direction and path.

Did you purchase or work on a Composite Research boat in 2016? If so, chances are you or your local wrench might have asked one of the following top five boating service and maintenance questions.

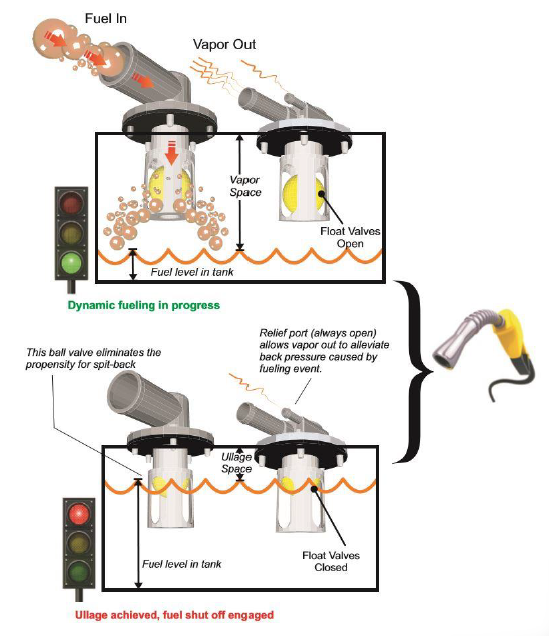

Over the past decade, requirements have been introduced to regulate marine fuel tanks to reduce their atmospheric emissions. These regulations though good for the environment have caused considerable issues for both boat owners and marine manufacturers alike. The largest issue is that owner’s are unable to completely fill a vessel’s fuel tank to the published or labeled capacities. The reason for this issue directly relates to the adoption and limitations of EPA’s approved Diurnal Fuel Systems.

Your boat’s fuel tank is required to have positive pressure (>1PSI) as the sun heats the vessel and the fuel in the tank expands. As such, the installed valves inside are designed to:

As a result, your fuel tank will have a varying capacity from the label or published capacity no less than 5% and up to 10% dependent upon the variation from static float due to equipment, and occupants, etc.

For example:

If your fuel tank has an approximate capacity of 68 gallons, you might experience a variance in total capacity of 64.6 to 61.2 gallons.

Note: Owners should only open the fuel cap for refueling. Pressure may be present when opening your deck fill, regardless of system type. The first time fuel is introduced to the a fuel tank, be aware of the interaction of cold raw fuel vapors replacing air, on occasion a vapor pressure can occur producing spit-back anomalies.

Further Troubleshooting

Should you experience a larger variance we recommend consulting your dealer to determine to check your fuel guage or fuel sender are operating correctly.

Topping off will override your fuel system design intent and could cause damage to your vessel due to overflow and will void any and all warranty claims related to fuel spillage. BlueSkies is expressly not responsible for any damage to your vessel subsequent to topping off.